Thinking Through Making

It's all about shaping the future with tools we haven’t invented yet.

Robotic Hot Wire Cutting

In this research and fabrication project, I explored the potential of hot wire cutting as a precise, low-waste method for producing architectural forms. Using an ABB industrial robot equipped with a custom hot wire end-effector, I developed a workflow to generate complex 3D geometries from foam blocks, resulting in outputs that could serve as molds for concrete casting, freestanding sculptural pieces, or modular wall systems, either in positive or negative form.

The process allows for highly controlled, smooth cuts with minimal material waste and no mechanical force, making it ideal for both conceptual prototyping and large-scale formwork production. Its ability to translate digital geometry into physical components with speed and precision makes hot wire cutting an invaluable tool in parametric design workflows, model making, and lightweight construction systems.

A key objective of this project was to optimize material usage in casting processes, exploring ways to reduce formwork waste by leveraging both the positive and negative foam outputs, and experimenting with efficient cut strategies to generate more sustainable fabrication techniques. Through robotic integration, the process not only increased precision and repeatability, but also opened new possibilities for customized, resource-conscious architectural components.

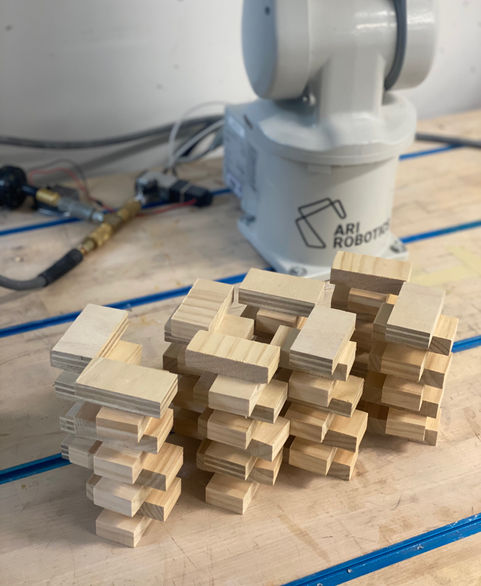

Pick-and-place Automation

This project explores robotic pick-and-place fabrication as a method for assembling masonry walls with parametric complexity and geometric precision beyond the limits of conventional, manual construction. By using an industrial robotic arm to autonomously pick up, position, and place individual bricks, we can choreograph spatial arrangements with nuanced rotations, subtle shifts, and complex bond patterns, movements that would be difficult or nearly impossible for a human to measure and execute in real time.

In traditional masonry, introducing even slight angular offsets or controlled misalignments requires extensive manual adjustment and is prone to human error. However, in a robotic workflow, these variations are simply numerical parameters, calculated digitally and executed with repeatable accuracy. This opens new opportunities for intricate, computationally generated wall designs, where each brick can serve a structural or performative role in relation to light, airflow, or acoustics.

As part of our research, we developed small-scale prototypes to test robotic behavior, motion planning, and material tolerances. Through iterative experimentation, we explored different wall configurations and assembly strategies, identifying challenges such as tool calibration, brick alignment, end-effector grip design, and tolerance compensation. These studies helped us understand how to translate digital design into physical construction using robotic pick-and-place, while optimizing efficiency and minimizing error.

This work contributes to the growing field of robotic masonry fabrication, where automation enhances not only construction speed and safety, but also enables new architectural expressions through precision, customization, and non-standard geometries.

Crooked to the millimetre: The technology pioneered by the ETH spin-off incon.ai allows blocks to be positioned with pinpoint accuracy, creating structures with aesthetic designs and augmented acoustics.

The Spaces in Between: Their column boasts an intricate design of oscillating, twisting triangles that expand and contract throughout the height of the structure. (IAAC)

What fabrication means for me ...

I see digital fabrication not just as a means of executing design, but as a powerful tool for generating new ideas and rethinking our relationship with materials. For me, fabrication is an active design process, one that provokes new ways of seeing, shaping, and engaging with form. It’s not about making what we already imagine; it’s about discovering what we couldn’t have imagined without the process itself.

In today’s evolving landscape of robotic arms, CNC machines, additive and subtractive manufacturing, and hybrid systems, the opportunities to experiment are endless. I’m particularly drawn to exploring the creative potential of these tools, and even more so, to the idea of designing new tools themselves. Whether through custom end-effectors, alternative workflows, or adaptive setups, I believe that innovation in architecture is deeply tied to innovation in how we fabricate.

Through my work, I’ve engaged with a wide range of fabrication technologies and continue to expand my skill set, always looking for ways to push boundaries. The idea of inventing a new fabrication method, or a tool that unlocks a new way of building, has long been a personal aspiration and remains at the heart of my design research.